- Service

Aircraft Cleaning

- Comprehensive Aeronautical Cleaning Service

Ensuring the image and performance of your fleet

This service ensures a flawless image in the passenger and crew cabins with different types of cleaning: terminal, deep, upholstery, and carpets, according to our clients' schedules. We also offer dry and wet cleaning for the fuselage and wings, improving not only their performance but also operational efficiency by reducing aircraft fuel consumption and reducing structural damage from corrosion due to environmental factors.

- What solutions do we provide?

Terminal Cleaning

Terminal cleaning is performed at the end of the last flight of the day. This procedure is carried out at the Main Base (MB) and is medium-to-deep, including the following:

- Emptying waste bins

- Cleaning of the passenger cabin, seats, bathrooms, galleys and cockpit

- Sanitization to ensure an adequate level of cleanliness for the next day of operation

Deep Cleaning

Deep cleaning is performed every 30 days at the Main Base (MB). This process includes areas not covered during in-transit or terminal cleaning:

- passenger cabin

- Seating

- Bathrooms

- Galleys

- Cockpit

Cleaning of Upholstery and Seats

This cleaning is carried out every 45 days at the Main Base (LIM) and is extensive. It includes:

- Vacuuming, brushing and stain removal of cushions, backrests, headboards and frames

- Cleaning rails and backrest compartments

Carpet Cleaning

Carpet cleaning is performed every 45 days at the Main Base (LIM) and includes:

- Vacuuming and removing garbage remains

- Application of specific cleaning products

- Brushing, stain removal and vacuuming

- Drying the surfaces

Fuselage Cleaning (Dry Cleaning)

This procedure is performed every 30 days at the Main Base (LIM) and includes cleaning, rinsing, and drying the following areas:

- Fuselage: lower area, upper area, radome, windows, windshield, access doors and APU chambers

- Engines: covers, pylons and compartments

- Loading: sweeping and vacuuming

- Stabilizers: vertical and horizontal

- Wings: upper and lower areas

- Landing gear: structure and wheel rims

Wing Washing (Wet Cleaning)

Wing washing is performed every 30 days or as requested by the operator at the Main Base (LIM). This process includes:

- Cleaning, washing and rinsing wings using specific degreasers

- Ensuring excellence on every flight

This comprehensive program ensures that each aircraft meets the highest standards of cleanliness and maintenance, providing a comfortable and safe experience for passengers and crew.

- We are here to help you!

Request More Information

Leave us your information and we'll coordinate the interior and exterior cleaning of your aircraft with the highest standards of quality and safety.

- More than a service, a certified commitment

Rigorous control, safety guaranteed at every step

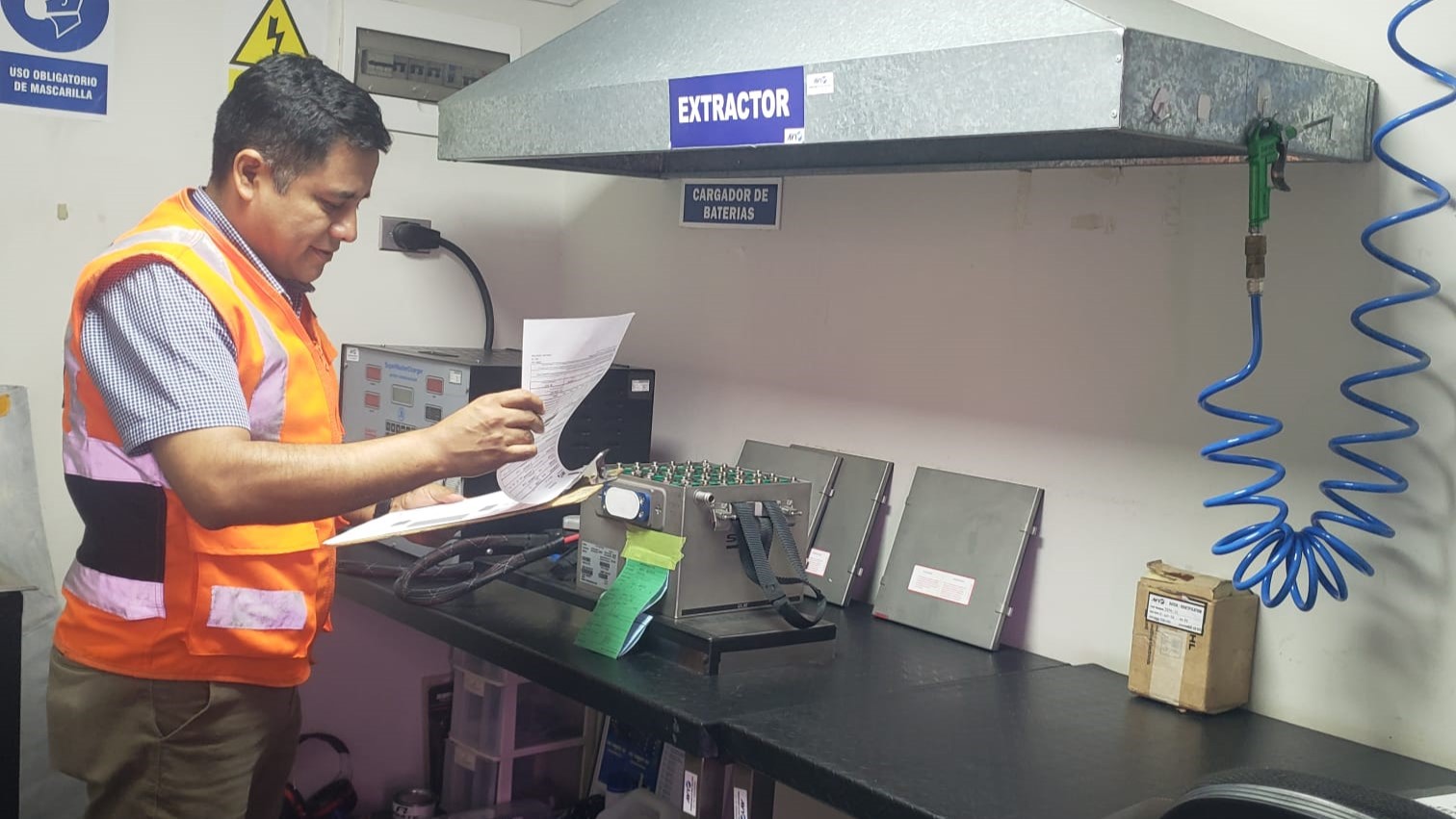

At AVIO, every activity goes beyond a simple technical task: it is supported by our Operational Safety and Quality Systems Management, which establishes and oversees the highest quality standards and the lowest possible risk levels. Through inspections, audits, and investigations, employing methodologies tailored to the aeronautical environment, such as MEDA, HFACS, ECFA, and 3CA, our team identifies and controls any deviations before, during, and after the service. We have an Integrated Management System (IMS) that, through its real-time dashboards, allows senior management and our clients to access detailed quality and traceability reports, fostering continuous improvement in each project.

- Quality Management

Through a rigorous audit and inspection program, we ensure that AVIO's processes comply with MRO standards (FAA, EASA, DGAC). We have also developed a surveillance plan in accordance with our clients' certifications (IOSA, BARS).

- Operational Safety

We have a robust, fully developed Safety Management System (SMS) that has been accepted by all the Civil Aviation Authorities that have certified us. A very important feature is our real-time tracking capability, which allows our clients to monitor the management of their reports and the risk levels under which AVIO operates.

Certifications that support each operation

We have national and international certifications that guarantee the quality, traceability and reliability of our aeronautical services.

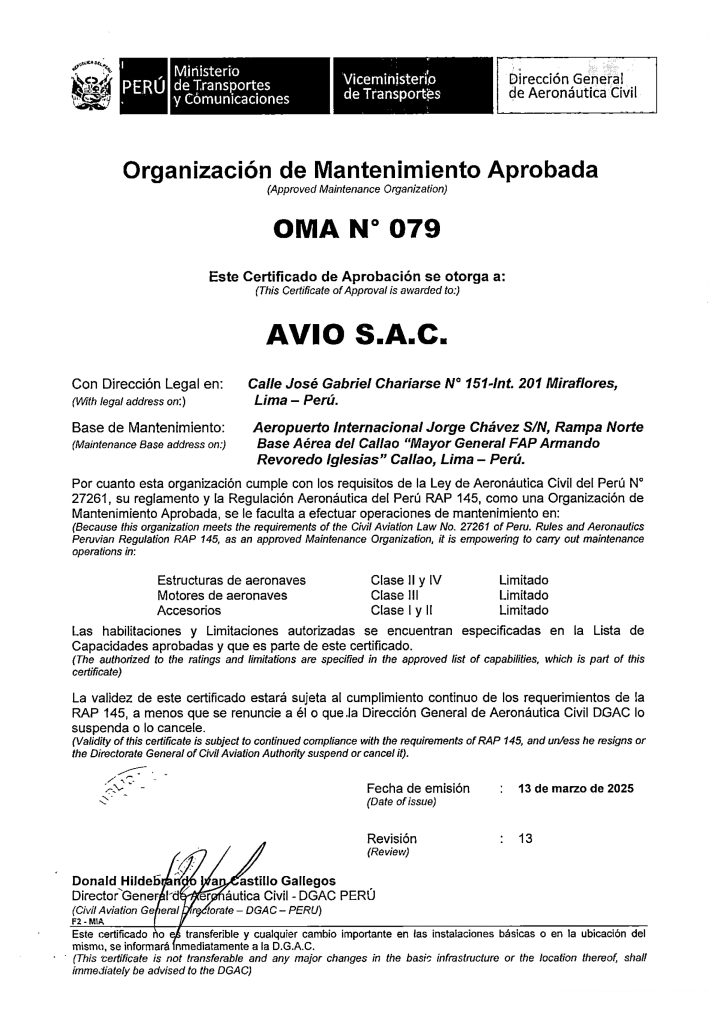

- DGAC Perú

Approved Maintenance Organization (OMA No. 079)

RAP 145 approval for maintenance of aircraft structures, engines and accessories.

- DGAC Chile

Foreign OMA Recognition (CMAE No. E-596)

Enables maintenance on Chilean aeronautical products and their components in accordance with DAR 145.

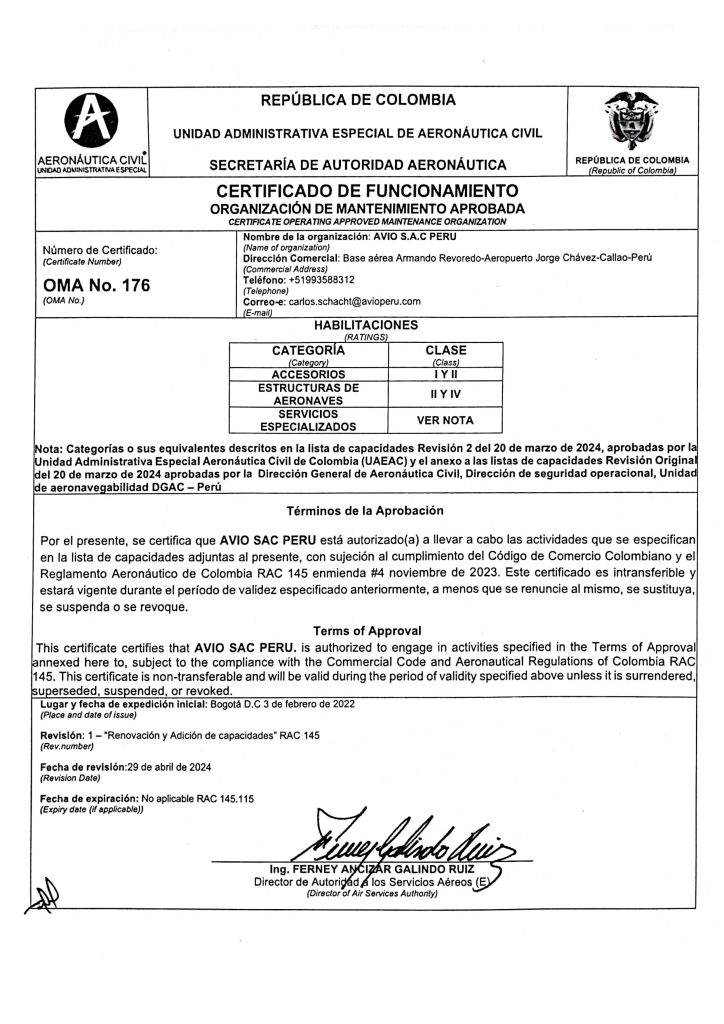

- UAEAC Colombia

Approved Maintenance Organization (OMA No. 176)

RAC 145 certificate for maintenance of accessories, structures and specialized services.

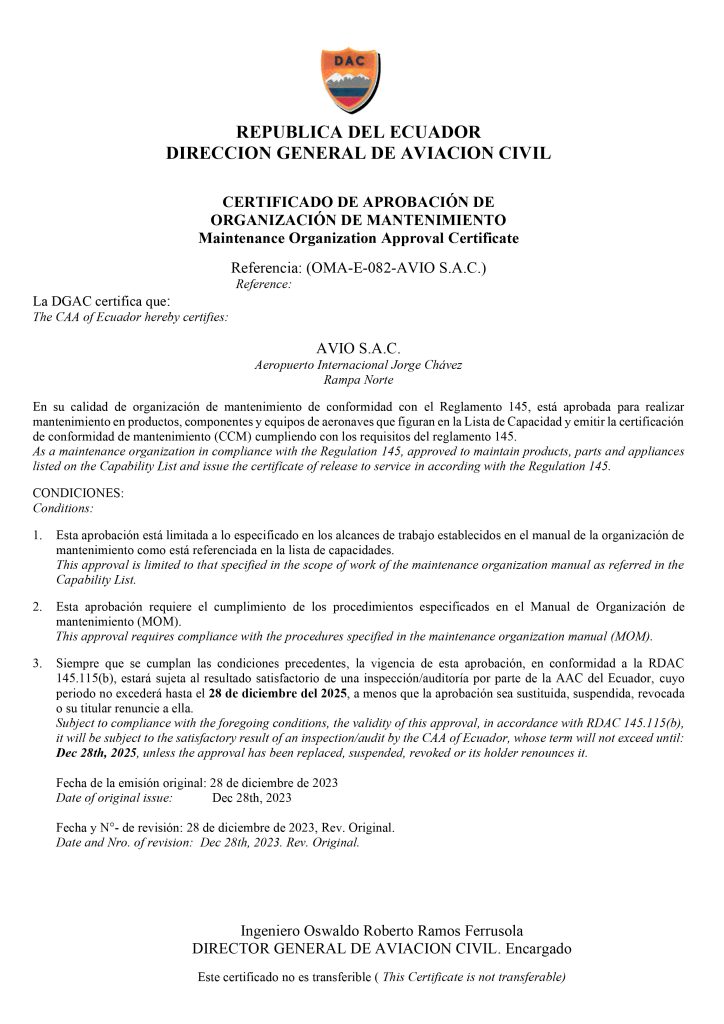

- DGAC Ecuador

OMA Approval Certificate (OMA-E-082)

RDAC 145 Approval for maintenance of aircraft, equipment and parts listed in the Capability List.

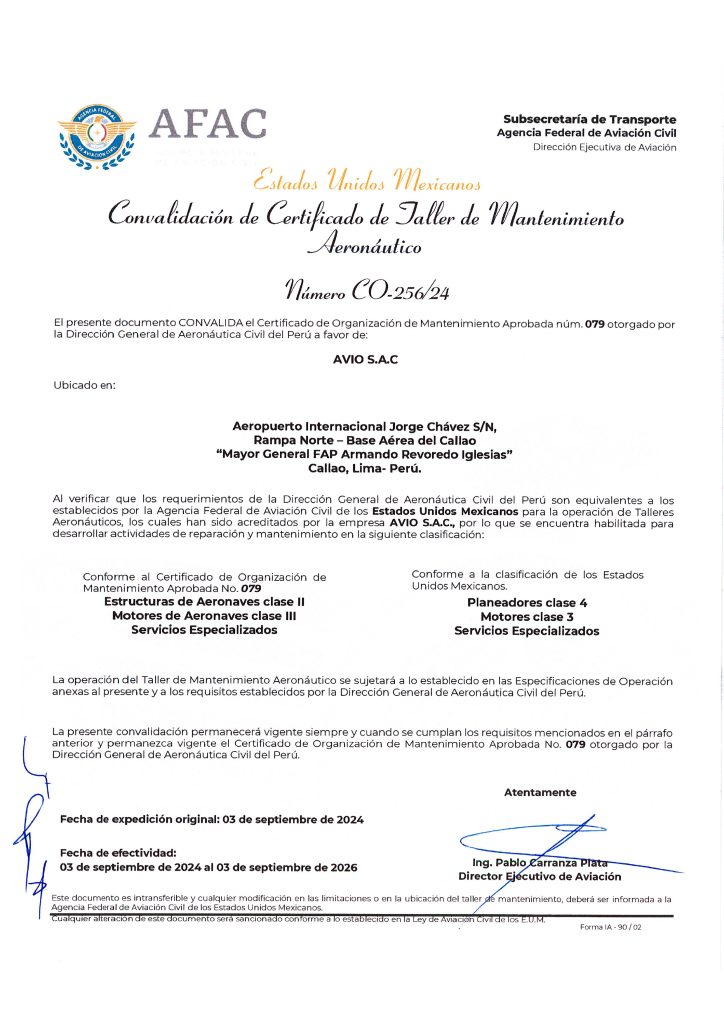

- AFAC México

Maintenance Workshop Validation (CO-256/24)

RAP 145 equivalence for structures (Class II), engines (Class III) and specialized services.

- FAA – Estados Unidos

Personal conlicencia Airframe & Power Plant (A&P) FAA

We are fully capable of increasing our capabilities at the request of our clients.

Airlines that trust us

We consolidate strategic alliances with leading airlines, thanks to our operational efficiency, response times, and high standards of technical compliance.

Ready to improve your fleet's performance?

With AVIO Peru, you have international support and top-level certifications so your aircraft will never be grounded.